Wire ropes are available in various types and constructions, each having specific uses. Therefore, it is important to select the rope according to the intended applications. Namely, it is necessary to see what properties are required for the rope to be used correctly. The properties cover breaking strength, flexibility, resistance to bending fatigue, anti-friction, resistance to deformation, non-rotation and anti-corrosion. In most cases, the key point of selecting the rope for a particular application is consideration of the above properties.

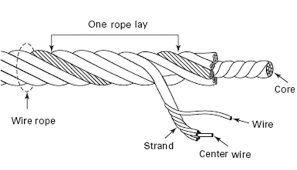

Wire Rope Construction

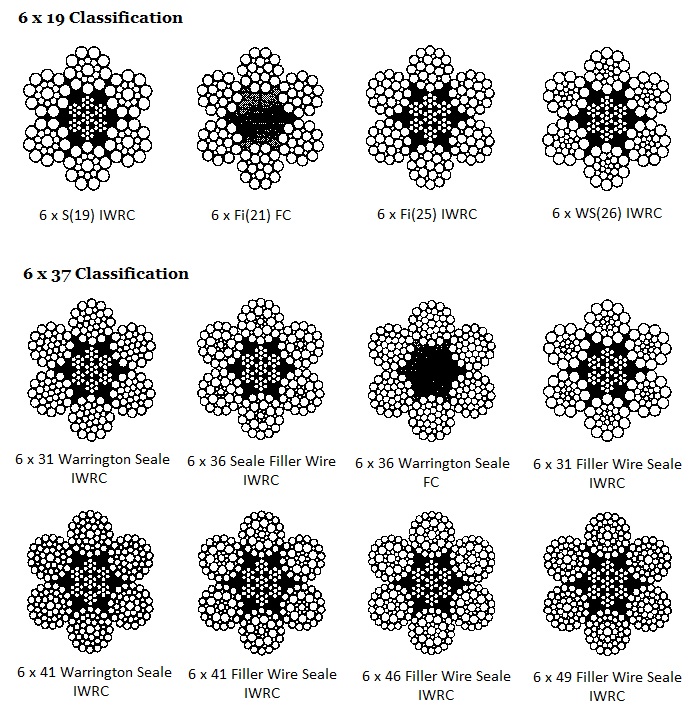

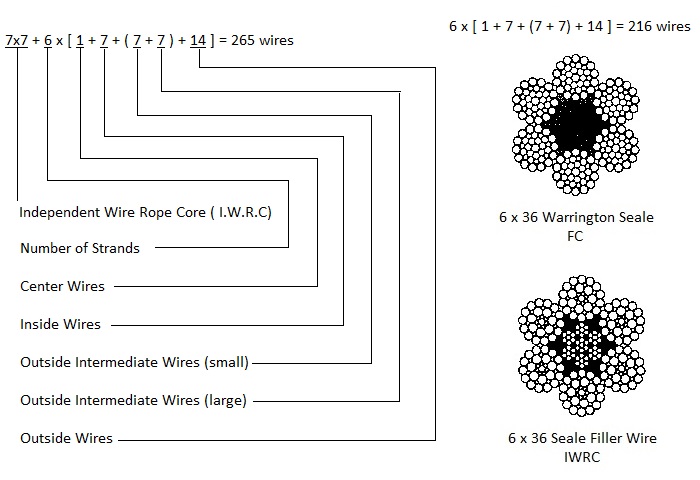

Wire Rope construction is indicated primarily by the number of strands and the number of wires in each strand. For instance a 6 x 37 steel wire rope is composed of 6 main strands and each strand has 37 main wires. These numbers are modified as follows:

- The arrangement of wires in the strand, i.e. Filler,

Seale, Warrington, etc. - Lay of stranding, i.e. regular, lang, right, left, etc.

- Outer covering, i. e. galvanized, ungalvanized, etc.

- Type of center, i.e. hemp core, I.W.C. and strand.

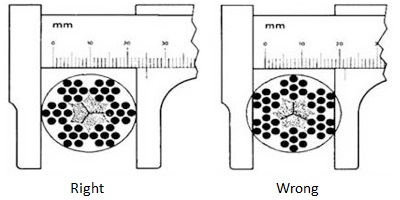

Gauging Wire Rope

The diameter of a wire rope is the diameter of the circle which will enclose all of its strands. When measuring a wire rope by a vernier caliper or digital caliper, care should be taken to measure the correct circumference of diameter of all the strands, not areas where there are two adjacent strands.

The Lays of Wire Rope

Wire ropes can be either Lang’s lay or Regular lay (Ordinary lay).

Lang’s lay construction is one in which the wires in the strand are laid in the same direction as the strands are laid into the rope.

Lang’s lay construction is one in which the wires in the strand are laid in the same direction as the strands are laid into the rope.

The advantage of using Lang’s lay is that a rope so constructed offers a better wearing surface when in use, and, therefore, can be expected in many cases to survive for a longer period than a rope made of regular lay. Lang’s lay ropes should never be used when one end of the rope is free to rotate.

Regular lay construction is one in which the strand wires are laid in one direction, and the completed strands laid into the rope in the opposite direction.

Nearly all ropes are supplied right-hand lay, but left-hand lay is occasionally required.

Nominal Tensile Strength

Referring to JIS G-3525

| Galvanized Wire Rope | Ungalvanized Wire Rope | ||

| Class | Tensile Strength N/mm ²(kgf/mm ²) |

Class | Tensile Strength N/mm ²(kgf/mm ²) |

| E G A B |

– 1470 (150) 1620 (165) 1770 (180) |

E G A B |

1320 (135) – 1620 (165) 1770 (180) |

API – 9A

| Nominal Grade | Class | Tensile Strength N/mm ² |

| 180 190 200 220 |

IPS EIPS – – |

1770 1860 1960 2160 |

IPS: Improved Plow Steel; EIPS: Extra Improved Plow Steel

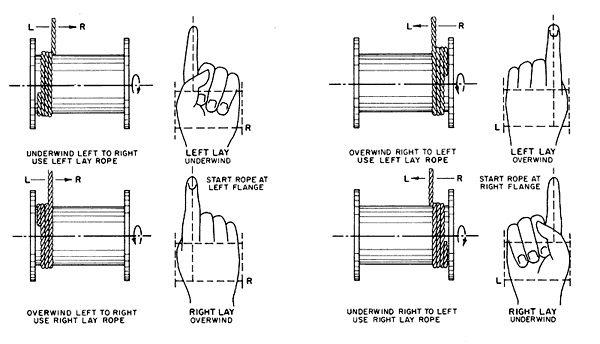

Winding Wire Rope

For Left-handed drum = right-hand rope; For right-handed drum = left-hand rope

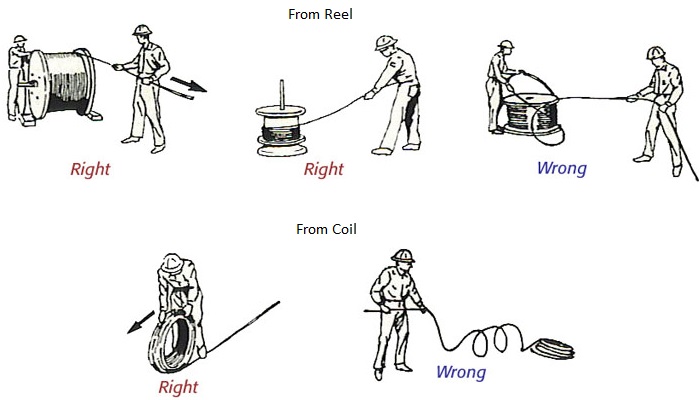

Unwinding Wire Rope

Cross Section of Wire Rope

A) Cross Lay (Conventional Lay)

The strands of a so-called conventional wire rope have equal-sized wires in all layers. Each layer has different length of lay and the wires of one layer cross the wires of the underlying layer.

When the strands are spun in this manner the wires of the individual layers are in point contact with each other. In conventional ropes, all wires, except for the center wire, are of the same length.

B) Parallel Lay ( Equal Lay)

The strands of equal lay ropes have wires of varying sizes laid in such a way that the wires of one layer are parallel with and supported over their total length by wires in underlying layers. All wires have the same length of lay, and are laid up in a single operation.

The use of equal lay strands avoids deformation, internal wear and secondary bending stress which result from the point contact between the wires in the conventional type. In most fields of application, equal lay ropes have proved to have a longer life than conventional ropes.

Wire Arrangement

Wire Rope Selection

- Where breaking strength is important, IWRC parallel lay ropes are recommended. For example: IWRC 6 x Fi(25), IWRC 6 x Fi(29), IWRC 6 x WS(36).

- Where flexibility is important, FC (Fiber Core) cross lay ropes are recommended. For example: 6 x 24FC, 6 x 37FC.

- Where resistance to bending fatigue is important, ropes made of strands with as many wires as possible are recommended. For example: FC 6 x WS(36), FC 6 x WS(41).

- Where anti-friction is important, ropes consisting of outer strands made of thick wires are recommended. For example: 6 x S(19), 6 x Fi(21), 6 x Fi(25).

- In case resistance to deformation is important, parallel lay ropes are recommended. For example: IWRC 6 x WS(31), U4 x SeS(39).

- Where non-rotation is required, non-rotating wire ropes are recommended. For example: U4 x Ses(39), 18 x 7, 19 x 7, etc.

- Where anti-corrosion is important, galvanized or stainless steel wire ropes are recommended.